Electrical energy is the lifeblood of the modern world. Whether you’re running a factory or operating an office building, you need a reliable and efficient electricity distribution system. Here compensation boards comes into play. These boards ensure the safe and effective distribution of electrical energy to different areas within a facility.

What are Compensation Panels?

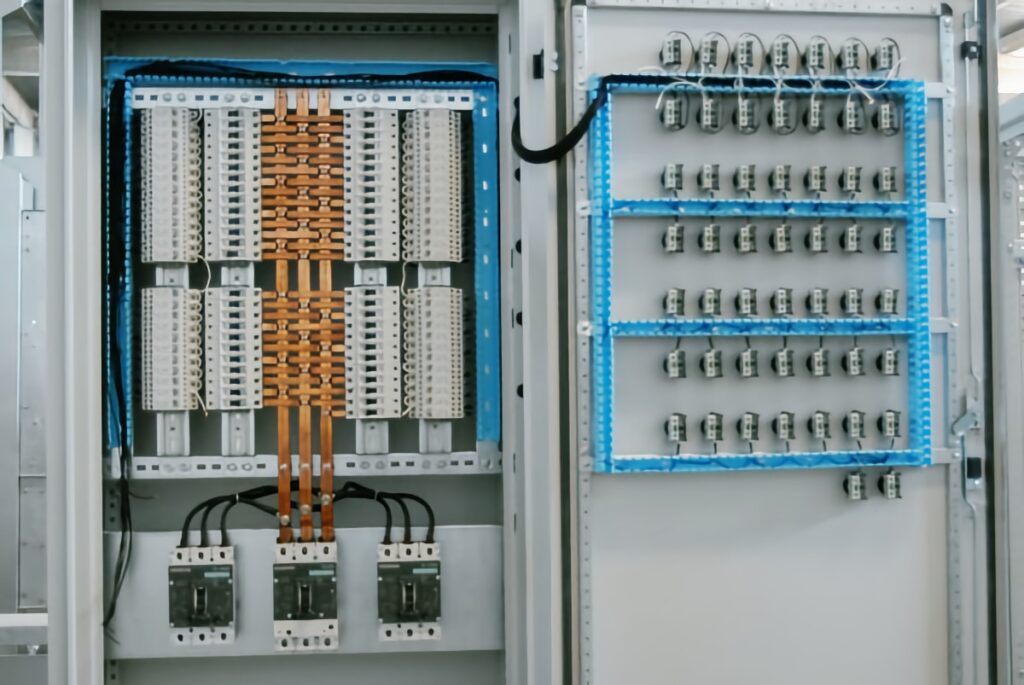

Compensation panels are the heart of an energy system. Electrical energy enters the panel through a supply line coming to the compensation panel. Circuit breakers and relays in the switchboard distribute the energy to different parts of the facility. This ensures that the energy is properly directed where it is needed.

Compensation boards take the energy and distribute it to a number of sub-boards. These sub-main distribution boards, then distributes it to specific areas, for example a specific office floor or factory area.

Compensation Panel Installation

Compensation board installation is a critical part of a facility’s electrical system. This process includes selecting the right equipment, placing it correctly and connecting it properly. This usually involves a series of complex electrical and mechanical tasks and is usually performed by a professional electrical engineer or contractor.

The installation process starts with the selection of the correct compensation board. This depends on the facility’s energy needs, existing electrical infrastructure and future expansion plans. It is important that the selected panel has the capacity and features to meet the needs of the facility.

Installation continues with the correct placement and connection of the board. This usually involves a series of complex electrical and mechanical tasks and is usually performed by a professional electrical engineer or contractor. Correct placement of the switchboard ensures efficient distribution of energy and minimizes potential safety risks.

Compensation Panel Design

Compensation board design is critical to meeting the energy needs of a facility. The design process takes into account the facility’s energy needs, existing infrastructure, and future expansion plans. The design also takes into account the dimensions and shape of the area where the panel will be placed, the equipment the panel will contain, and the overall functionality of the panel.

The design process usually includes a series of detailed technical drawings and plans. These drawings show the dimensions, layout, internal equipment and connections of the switchboard. These drawings are usually a OG cell concrete kiosk is provided by AG panel product supply and logistics process management service.

Industrial Compensation Panels

Industrial facilities often require large amounts of electrical energy and need powerful compensation boards to manage this energy effectively. Industrial compensation panels usually supply energy to a series of sub-boards, which distribute the energy to different parts of the facility.

Industrial compensation boards often contain high-capacity circuit breakers and relays. This ensures that large amounts of energy are dissipated safely and effectively. Also, industrial compensation boards often include a number of safety features, for example overload protection and short circuit protection.

Compensation Panel Hardware

Compensation board hardware enables a compensation board to work effectively. This equipment consists of circuit breakers, relays, fuses and other control devices. These devices ensure the correct distribution of energy and prevent potential problems such as overload or short circuit.

The equipment of a compensation board generally depends on the type and usage of the board. For example, a compensation board, capacitors and reactors to balance reactive power a PLC-controlled conventional synchronization board</a > includes programmable logic controllers (PLC) to synchronize multiple energy sources.

Result

Compensation boards enable modern plants to operate effectively and safely. These boards take energy and distribute it to different parts of a facility, thus meeting their energy needs. Compensation board installation and design is critical to meeting a facility’s energy needs and is often required by a professional electrical engineer. performed by the engineer or contractor.

Industrial plants often require large amounts of energy and need powerful compensation panels to manage this energy. These switchboards often contain high-capacity circuit breakers and relays and distribute energy to different parts of the facility safely and effectively.

Compensation board hardware enables a compensation board to work effectively. These equipment ensure the correct distribution of energy and prevent potential problems such as overload or short circuit.